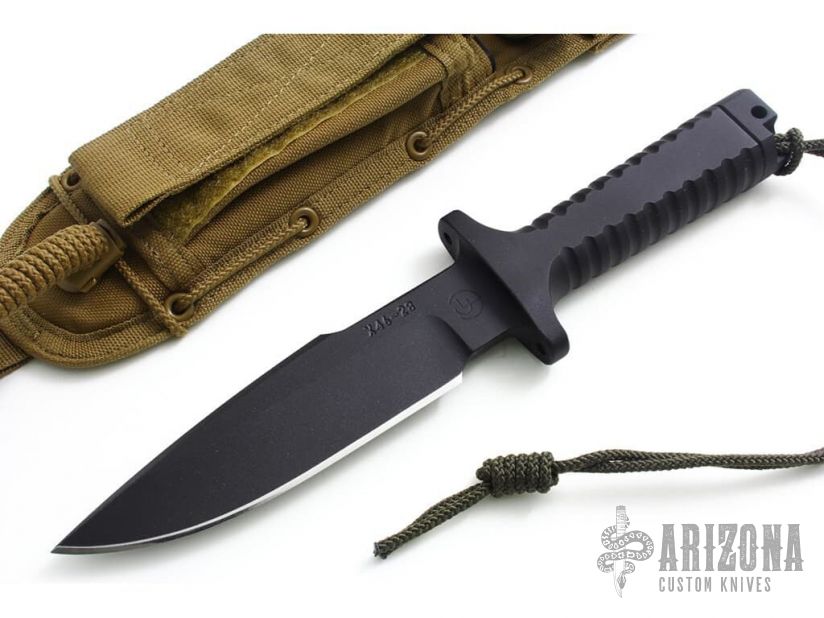

Model X-46

Price $395.00

Product Details

Blade Length 6.125

Overall Length 11.125

Weight (oz) 19

Additional Specs

Knife Type Has Sheath

Blade Material A2

About the Maker

Franco, Andy

Visit this maker's website: Cailco Forge Knife Co.. "I'm a knife maker in Nampa, Idaho. I've been forging blades for 7 years now. I draw my experience from years of making a living as a blacksmith. Although I have made many things in the past, nothing is more enjoyable to me than making knives. What really motivates me to build knives is the idea that what I make gets used in the field. Creating something from raw material into a useful, practical and essential tool that will be used for years is rewarding. It's in the knowing that what I design and create is not in vain, but lasting. Making knives is more than just a trade or skill, but a way I can express myself in perpetuating what I believe. In my earlier days I became very aware of the value of a good knife. I've had many jobs that placed me in difficult situations where a dependable knife was required. From working as a crab fisherman in the Bering Sea, ranch hand up in the North Idaho pan handle, fur trapping along the Flathead in Montana, serving in the U.S. 75th Army Rangers (Airborne), or just hunting mule deer in Southern Utah, I learned the importance of a well made and dependable knife. Sometimes the hard way. If you don't have a good knife with you, you have nothing......... My Philosophy - The Working Knife My construction/design influence derives from the great old American West and the rugged individualism, courage, pioneering spirit of those brave souls who settled it. The knife represents independence, freedom, self reliance, skill and endurance. Knives should be sharp, rugged, tough, practical and look good. Knives should be made to be used. Knives are tools, not jewelry. If a knife looks to nice to be used, then it's too nice. Making knives is my passion and pursuit. The art of knife making is a study and discipline that I take very seriously. I continuously strive to improve the quality, design, durability, strength and integrity of each knife that I make. Every knife I build, I continue to bare in mind the man who will eventually own it..... knowing that some day his life may depend on it. My Knives Every knife that I make is hand made individually in my shop here in Nampa, Idaho. Each knife is made one at a time and is inspected, tested for quality, durability and detail before leaving the shop. I hand forge all my blades the old fashioned way, hammer & anvil. I use only quality high carbon steel on all my knives. I differentially heat treat and temper all my blades. I hand select all my handle material from premium grade Elk, deer, moose and stag antler. All my leather sheaths are made by me as well. I use quality top grade 10 oz. vegetable tanned cow hide. Each sheath is hand fitted and hand stitched to every knife. My goal is simply this: Make knives the way they use to be made 100 years ago,.....today."

Robson Knives by RPW, Inc

John Robson Our story: My Dad is an elite welder, he formed RPW to allow him to fulfill his missionary urgings. He put a torch in my hand when was I was 5. I manipulated metal under the constant gaze of this master metal man. At 15 I earned certifications in metal craft reserved for the highest quality fabricators. The Macedonian call demanded more of my Dad's time, consequently at 17 the responsibility of the fabrication business was placed on my shoulders. A dubious promotion at best. My fabrication skills and design knowledge held the day while I learned to manage RPW. We at RPW follow the standard instilled by my father. Hard work! Skilled work! Masterful design! Under this banner RPW knives are crafted.