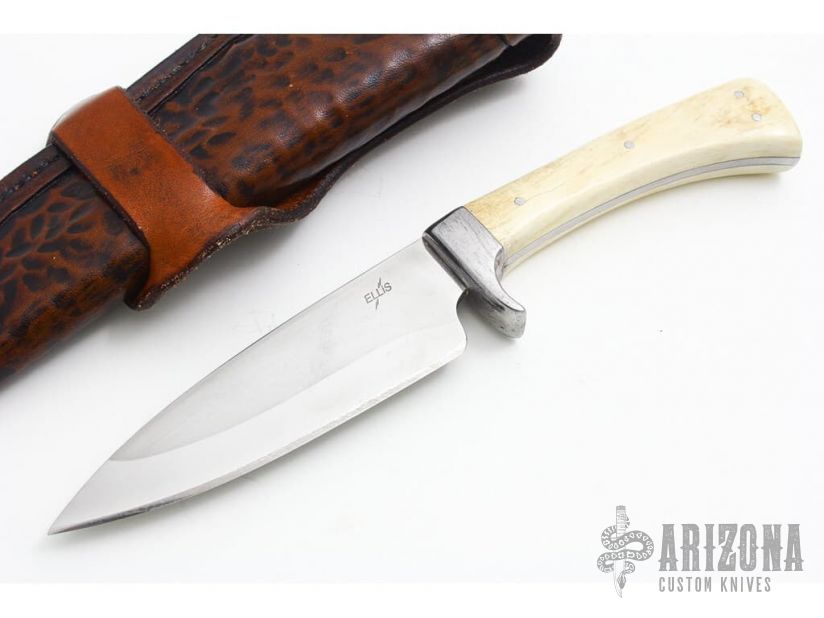

Product Details

Blade Length 4.5

Overall Length 8.75

Weight (oz) 5.4

Source From maker

Additional Specs

Knife Type Full Tang, Has Sheath

Blade Details Drop Point

Handle Material Tusk & Tooth

About the Maker

Ellis Ironworks, Dean

Hi. My name is Dean Ellis. I live in Montana. If you want to talk forging, knives or anything else related to blacksmithing, just give me a call. All of my blacksmithing is done on a coke fired forge. I have a passion for making knives but I also do some other blacksmithing when the mood strikes me. I like the look of some old period knives so that is what my style is based on. I hand forge each blade, spring and bolster so each knife is unique. The metal is usually blued or browned to give it a period look, but I can leave it polished. I generally use 52100 steel because it makes a good working knife and that is what I like. I also make forge welded damascus for blades. Bolster material is either turn of the century wrought iron (some from bolts found at a Montana mine site), stainless steel, brass or damascus (forged from chainsaw, motorcycle, bicycle chain, or wire cable). I use natural materials for the handles such as wooly mammoth ivory, oosic (google that!), sheep or elk horn, giraffe, camel or buffalo bone. I started out making fixed blade knives, but enjoy the challenge of folders - friction, lockback and slipjoint. I still make fixed blades. My newest challenge is an integral fixed blade where the bolster is part of the knife blade. I do 100% of the work on each knife myself from creating the pattern to putting the final edge on each blade.